All in Design Engineering

Announcement: We have recently released new wallet sized stainless steel engineering reference cards for purchase in our store! Use them as durable reference cards while in the field or as convenient reference information while in the office. Reference information includes: weld symbols, GD&T symbols, and a drill & tap chart.

Metal foam is a porous material consisting of open-cell, closed-cell, or composite cavities. Open-cell metal foam has an interconnected network of pores. Closed-cell metal foam is similar to open-cell, but is sealed and may not have interconnectivity of internal pores. Composite metal foam combines a matrix of hollow metal beads of one material, such as steel or nickel, within another material, such as aluminum.

Melted solder is attracted to metal but will not stick easily to metal with oils and oxidization. Flux melts at lower temperatures than solder alloys and is used to coat the area to be soldered and guarantee a clean joint. Flux helps draw solder into a joint and makes it easier to create a capillary action.

During all aspects of design engineering, it is critical to ask how the design will be manufactured. “precision tools of the trade” explores manufacturing through the tools used to inspect and monitor designs as a part or assembly moves through an engineering process.

Buoyancy is the upward force on an object that counteracts gravity and other downward forces present. A submerged object in some fluid medium will experience a force due to gravity, a force due to buoyancy, forces due to wave energy, and other forces - the net force will determine whether the object floats or sinks and its rotation.

Each digital caliper, after being subjected to grinding dust, coolant splash, machining chips, and being handled by multiple people, has kept readings within .0005” of the target value. This means the calipers have not degenerated in accuracy at all with respect to the manufacturer’s given resolution and measurement accuracy numbers.

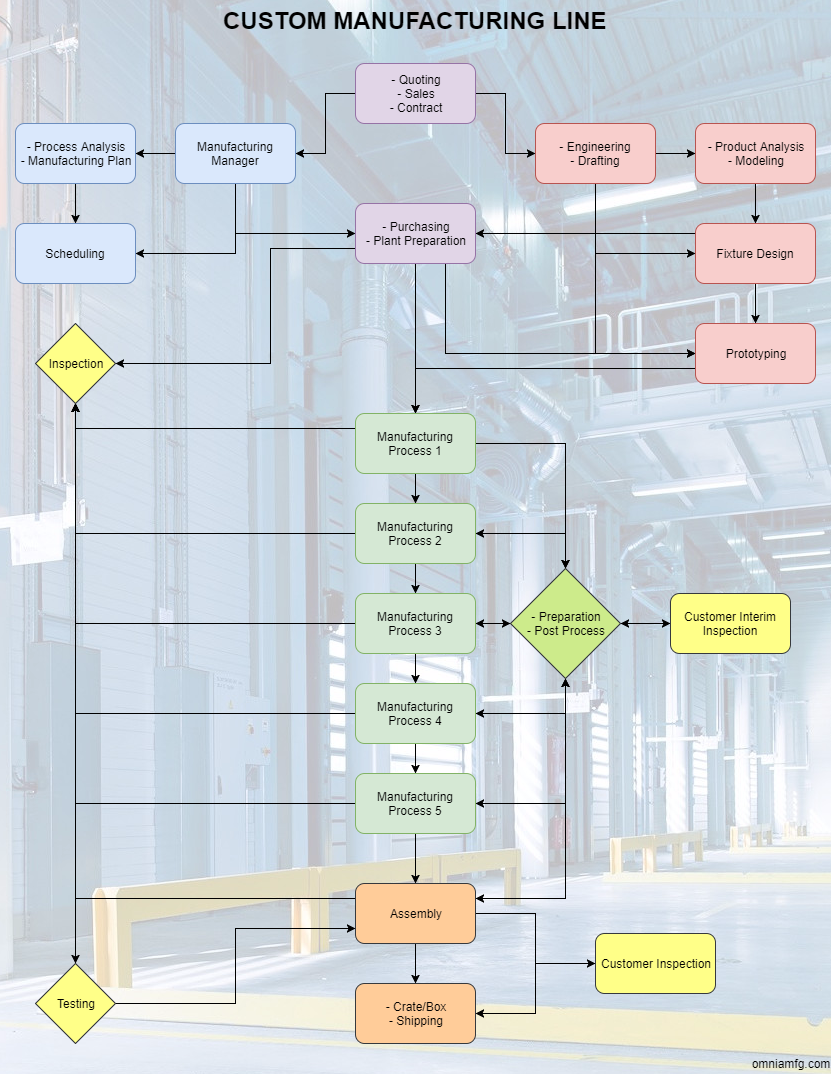

Custom manufacturing facilities engineer manufacturing processes for a wide range of products primarily in low volume and at a variety of complexity. Engineers and highly detail oriented employees create a culture of fast paced process and product analysis...

Design engineering and manufacturing engineering should be closely tied together in practical applications; therefore, it is important to fully understand what a pitch diameter is and how the tolerance range may dictate the best design/manufacturability ratio...

Focusing on sheet metal, it is important to be able to transfer model files between your company a supplier company or vice versa seamlessly.