Video - What is the Fillet Weld Joint

Video Summary

Below is a summary of the topics covered in Brent’s video. For the full effect and lesson including illustrations and examples, I recommend watching all the way through.

What is a fillet weld?

Joining 2 pieces of metal with a weld in an approximately triangular cross section.

T joint – A welded structure where two pieces of metal are joined perpendicular to each other.

Lap joint – A welded structure where two pieces of metal are joined overlapping each other and parallel to each other.

Corner joint – A butt joint welded structure where two pieces of metal are joined at a right angle, forming a corner.

What Does the Weld Look Like?

The fillet weld will be shaped and inspected as a flat, concave, or convex cross section. This will be a requirement directed by the welding symbol on the engineering drawings.

How Will the Welds Be Inspected?

Flat – The flat shaped weld will be inspected as is for strength. The inspection will take into account the distance from the root of the welded joint to the flat surface of the weld finish.

Convex – The convex shaped weld will be inspected to a straight line from ends of convex radius (throat to line) to determine the strength of the weld.

Concave – The concave shaped weld will be inspected to a straight line that is drawn tangent to the concave radius (throat to line) to determine the strength of the weld.

Fillet Weld Terms

Leg – The length of the horizontal or vertical length of the fillet weld cross section.

Root – The point at which the two pieces of metal come together to form the joint that will be welded.

Face – The surface of the fillet weld.

Toe – The ends of the fillet weld when viewed as a triangular cross section.

Throat – The distance between the root of the weld and the face of the weld.

Penetration – The depth at which the fusion line extends below the surface of the metal joint being welded.

The video was produced by Brent Harkness at TVWeld. Check his channel out here:

For some additional welding resources, take a look at these posts:

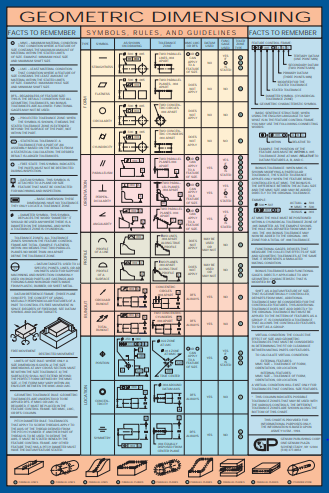

Welding Standards - Engineering Drawings - Elements of the Weld Callout

Material Shrinkage Properties in Welding

Jarrett Linowes

Mechanical Engineer

omniamfg@gmail.com

Did I miss anything you are interested in? Send me an email or comment below!